Warning: To Avoid Injury From Unexpected.

#ATLAS LATHE BELT CHANGE MANUAL#

And if that is not enough reason, note that link belts are available just a little longer than you think you need, then you can change the number of links you use in order to get a good fit. Craftsman 113.228360 Manual Online: basic lathe operation, Changing Speeds.

And (assuming you are replacing the belt anyway) you can just cut the old belt so you don't need to disassemble all that stuff just in order to get it off. at ) A link belt doesn't have to go over the end of the shaft, so it can be installed with all those parts in place. (Either look at the lathe and the countershaft or see the diagrams in the manual, e.g.

#ATLAS LATHE BELT CHANGE INSTALL#

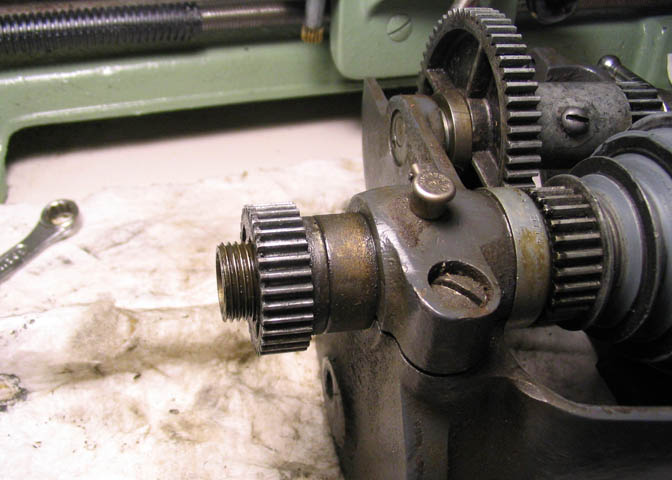

If you are new to this and want/need to replace a belt, take a moment to see how much you have to disassemble and later reassemble (if you remembered to make a drawing or take pictures so you can actually do it in finite time!) in order to install an ordinary belt, one that has to be slid around the end of a shaft. Some of the replies do mention "link" belts but nobody has bothered to point out why they are good to use. It looks > like the spindle must come out to replace the spindle drive belt with > a regular vee belt. > The belts are rotten, he says it uses a 3L200 and a 3元50. After I did all this, I found a nice Logan so I cleaned the Atlas up, made a big storage wooden box for it and it has been stored for over 2 years. Quote:> A friend just got a nice little 6' Atlas lathe, from a friend of his > who bought it new in the 1940s. After obtaining a very good step pulley, I finally just replaced the belt with a 3L link belt. Am not sure if this helps but, I recall an old buddy of mine bought a new Atlas in the late 70's,and it had a very slim belt on it as well. All I know is when a 3L belt is used, it sticks up quite a bit from the OD of the pulley due to it's 3/8" width. Now, I don't know what a 2L belt measures, but maybe it will work. Reason being, I would imagine, was that a 3L belt had been used for a very long time. Looking at the old pulley, I could tell that it had been worn considerably. Dummy me! I measured the groove width of one of the other pulleys that had not been worn near as much and that was when I found that it was only 11/32" wide. When I finished the blank, It was longer than it should have been. I used the dimensions for the pulley grooves from my Machinists Handbook.

#ATLAS LATHE BELT CHANGE FULL#

I never really did a full measurement of the old one. Lathes, drill presses, metal cutting band saws, mills, surface grinders, CNC equipment.all Clausing products are backed by the friendly and resourceful staff.

I assumed the grooves would fit a 3L belt since that was what I had measured on the old one. How do I know this? The main head stock step pulley on my Atlas needed replaced due to the 20 tooth gear was worn quite badly. Actually, the belts on my 1939 Atlas 6" lathe are special belts.The top/wide part actually measures 11/32".

0 kommentar(er)

0 kommentar(er)